Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

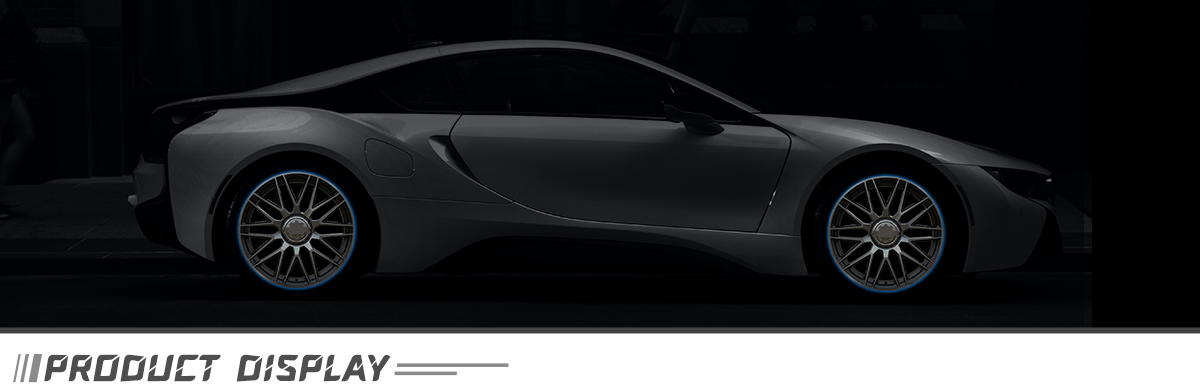

Aluminum Replica Car Korean car alloy wheels for HYUNDAL Kona

The quality of the aluminum alloy used in the materials is an important factor in making high-quality wheels. The structure of the aluminum alloy is also an important factor, which is based on the difference between cast and forged wheels.

FITMENT SIZE ET PCD CB

HYUNDAL 1875 45-50.5 5*114.3 67.1

HYUNDAL 1980 45-50.5 5*114.3 67.1

The quality of the aluminum alloy used in the materials is an important factor in making high-quality wheels. The structure of the aluminum alloy is also an important factor, which is based on the difference between cast and forged wheels. The cast wheel offers greater strength-to-weight ratios than a forged rim, but its production process offers less flexibility for design and weight reduction. A forged wheel, by contrast, offers more design freedom with reduced weight than a cast wheel; it also makes it possible to use fewer but stronger spokes or even thinner walls around a single spoke or in the entire rim.

Features

An aluminum alloy wheel is a rim that is made from a cast or forged high-strength aluminum alloy.

In the case of casting, this is done by injecting molten aluminum into a sand or ceramic mold to produce the shape.

In the case of forging, it is using techniques such as press forging to form parts with complex shapes.

Advantages

The high strength of the alloy permits thinner cross-section rims and spokes, allowing the wheels of moderate or even very light weight to be done without sacrificing safety. From the standpoint of appearance, chrome-plated aluminum alloy rims are highly desirable on motorcycles and luxury automobiles.

Benefits

The primary benefit of forged wheels is their greater strength (in tension and compression) over a similar cast wheel.

The precise nature of the benefits will differ according to how their relative strengths and weakness compare during use, but because they suffer less stress during use as well!

Misunderstanding of aluminum alloy wheel repair

Generally speaking, the fracture or crack of the aluminum alloy wheel can be repaired by welding, but from a scientific point of view, the metal crystal structure at the weld after welding is completely different from the metal structure of the normal wheel. The metal of the normal wheel is In the molten state, it is gradually cooled and crystallized under a certain pressure, and then quenched and tempered by solid melting and aging treatment. Welding is only a process of local melting and resolidification. The welded hub must have weld stress at the weld. After a period of load operation, it is very likely that fatigue cracks will occur in the high stress area of the hub, resulting in fracture. If not detected in time, there may be serious consequences.

Similarly, if your aluminum alloy wheel is deformed by an external force and is forcibly restored to its original state by an external force in the repair shop, even if your wheel is fortunately not produced in these two plastic deformations, there are no small cracks that we cannot detect with the naked eye, then The overall stress distribution of the wheel hub has also undergone major changes from the original design, followed by the generation of unpredictable fatigue cracks somewhere, and then fractures.

As for the scratches on the surface of the wheel hub, we suggest that there is no need to deal with small scratches, because the scratches mainly appear on the front wheel, and most of them are on the right front wheel. If it is for aesthetic reasons, you can choose to use this wheel as a spare tire. Aluminum has a characteristic that when exposed to a corrosive environment for a long time, a dense oxide protective film will be formed on its surface to prevent further oxidation of the body, so there is no need to worry about it being corroded. If the scratches are relatively large, it is recommended to replace the hub, because the design of the hub is that the surface of the spoke does not protrude beyond the tire. If there are large scratches on the surface of your hub, it must have been hit a lot, so For the reasons described above, it is best to replace the wheel with a new one.